Project Scope

The trial project was started in early 2017. CET has to...

- Prove that its PQ monitor (PMC-680i) complies with all PQ measurement requirements

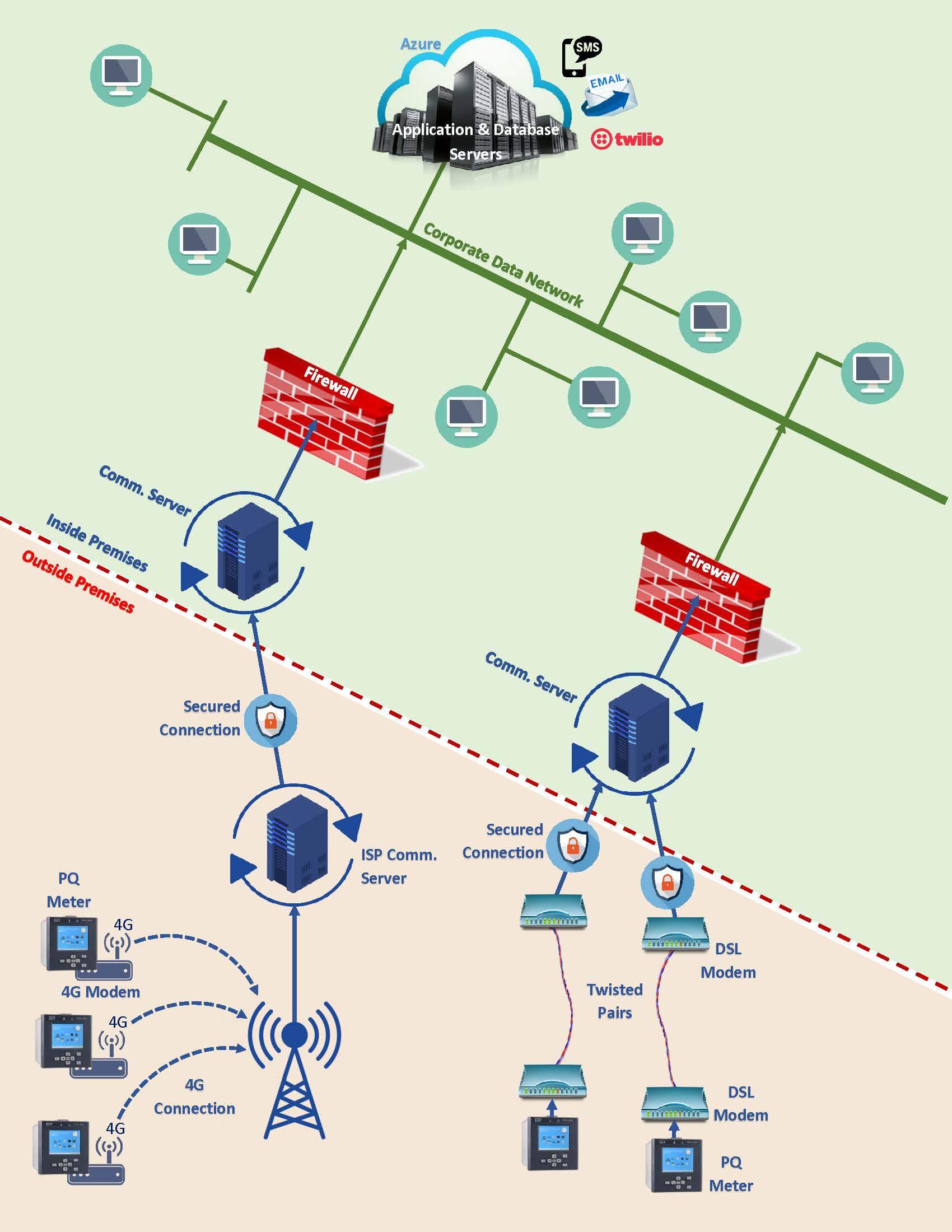

- Support data transmission from PQ monitors installed at remote substations to the PQ monitoring software through Ethernet, twisted pair wires or wireless solution

- Supply an Open System (PecStar iEMS) to integrate the existing 500 PQ monitors throughout the network and demonstrate the ability to integrate PQ monitors from different suppliers

- Send a notification Email & SMS within 60s after the occurrence of a PQ event

- Generate predefined PQ reports for performance evaluation

Challenge

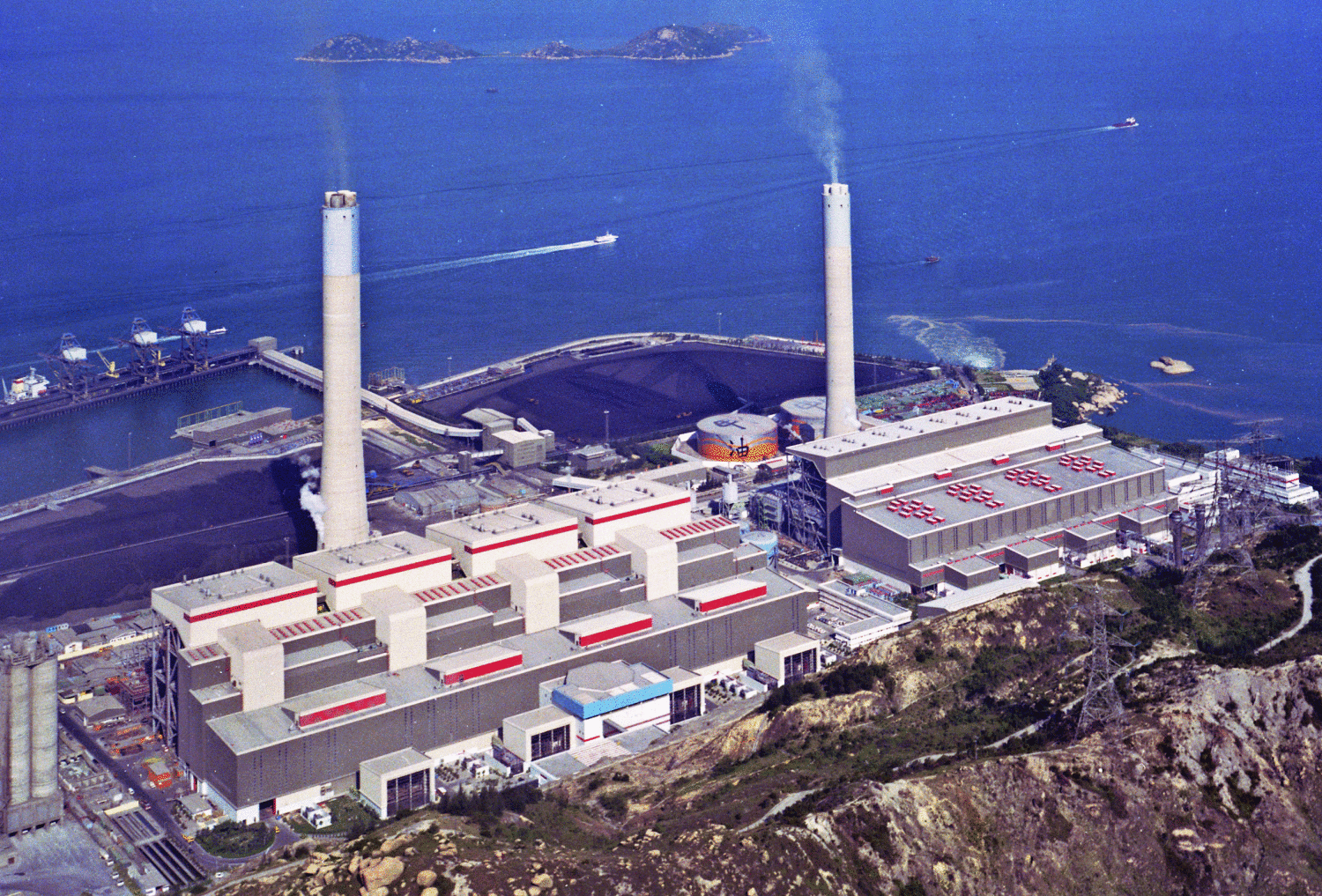

Site installations:

CET's PMC-680i completely complies with customer's measurement requirements not only for its IEC 61000-4-30 (Class A) PQ Compliance certification but also for other data recording capability. One of the major challenges is the absence of internet access at remote area. Therefore, it’s extremely critical for CET’s PecStar iEMS and PMC-680i to support 4G and DSL modem connections for remote locations.

PQ Platform:

The PecStar iEMS® supports multiple communication standards and protocols. It is a powerful platform for the integration of CET’s and 3rd-party PQ monitors from major suppliers through its large protocol library. However, the major challenge is the processing speed for collecting events from a minimum of 500 PQ monitors and then reporting PQ event notification via Email and SMS within 60s.

Solution & Result

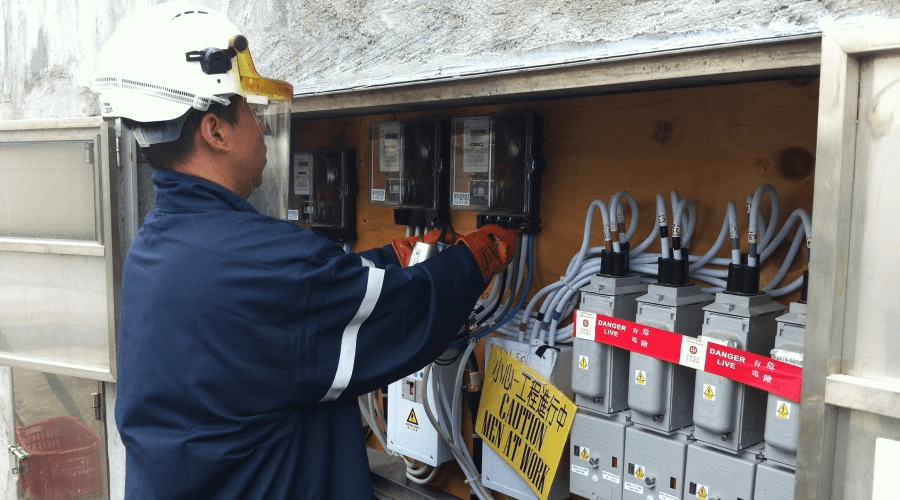

Site installations:

Due to the absence of internet access at remote sites, 4G and DSL modem connections are 2 possible ways for establishing communication between PecStar iEMS with the PQ monitors installed at remote substations. Due to the noisy condition in long distance transmission via twisted pair wires, it would take approximately 2 minutes to receive a complex message, such as a waveform record, from a PQ monitor. This performance is deemed totally unacceptable from the system point of view because of utility’s tight timing requirement for PQ event notification. CET is able to overcome this problem with an effective error handling scheme with an enhanced device driver and improve the communication time from 2 minutes to 5 seconds.

PQ Platform:

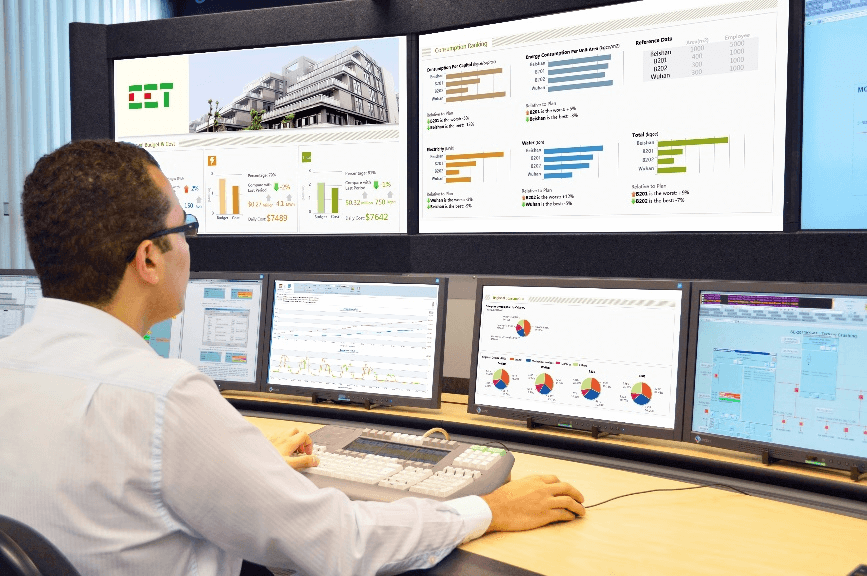

The PecStar® iEMS is a unifying application for Power Quality Monitoring and Energy Management that integrates Data Acquisition, Database Management as well as Web services and offers comprehensive Data Analysis and customizable Reporting Tools.

The PecStar iEMS has met all customer’s software requirements, but there remains a system performance issue of collecting event data from 500 PQ monitors within 60s. Due to the large amount of data transmission is involved after the occurrence of a PQ event, the waveform data, event data, real-time data and log data would need to be prioritized. A simple optimization has been made in the device driver to give higher priority to event data so that the PecStar iEMS software is able to consolidate the event data and dispatch the urgent notification message within the required target time of 60 seconds. As a result, PecStar iEMS could collect all the event data from 500 PQ monitors within 15s, exceeding customer's performance expectation.

Finally, the trial system has been tested successfully and has acquired utility’s approval as a qualified system. This trial system has also proved that CET’s PecStar iEMS® is an open system platform that can handle different 3rd-party PQ monitors and is capable of handling a large amount of PQ data from a big PQ system intelligently and efficiently.